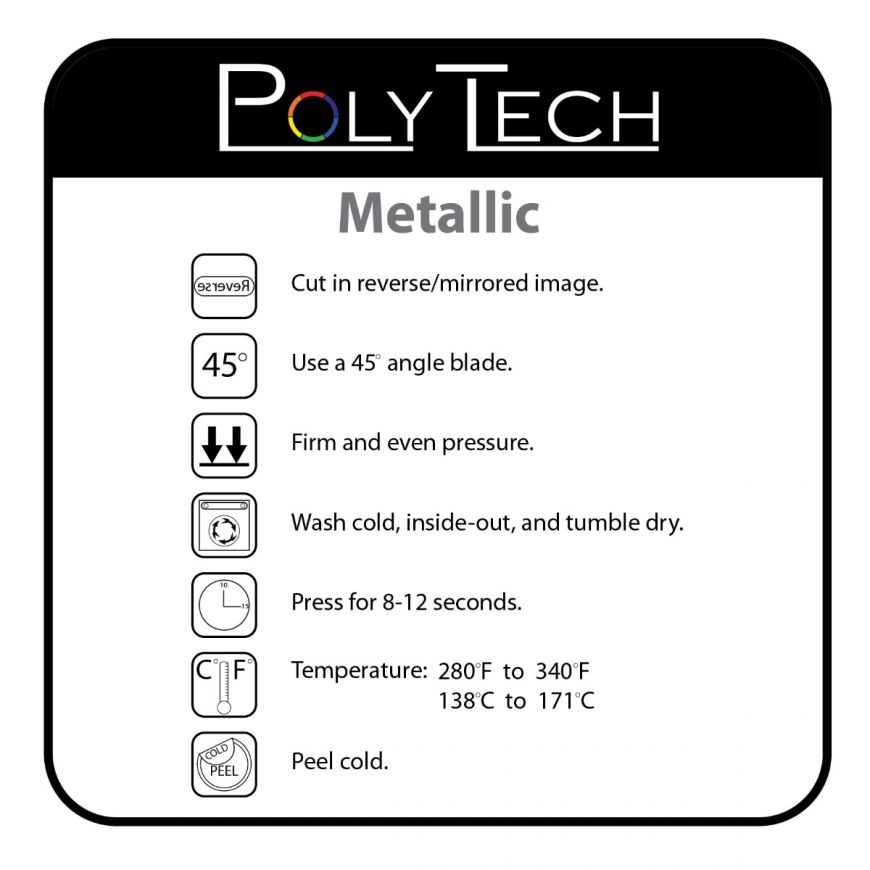

A lower angle 45 degree is great for thin materials while a steeper angle 60 degrees has a more vertical cutting orientation that penetrates deeper.

What is the best angle blade to cut metallic vinyl.

If the blade angle isn t high enough the blade can actually drag through the material and create vinyl ears causing a poor quality cut.

This blade has a steeper blade angle 60 degrees vs 45 degrees for the other fine point blades and harder more durable steel.

Mh series vinyl cutter compatible blades choice of 45 60 deg or assortment rationale for blades of different angles.

Because not all of the blade s cutting area is used you will also need to change blades more frequently since the sharper.

Inversely using a 60 degree blade on everything is a waste of a blade.

A curve cutting blade a metal cutting blade and a general purpose blade.

It comes with 3 additional blades.

The black decker 3 4 amp navigator combo set is an excellent option.

For those who want to cut reflective and other materials in a graphtec or vinyl express qe or q series plotter the economical option is to use an aftermarket 0 9mm blade with a 60 angle.

If you find your fine point blade just doesn t want to cut through a material thicker than standard cardstock this is the blade to use.

It has a 4600 spm motor and can cut wood metal and plastic.

These may allow you to cut grooves under doorjambs and snugly place the planks underneath.

If your 3m vinyl is wider than 24 you may need to add a pinch roller to your plotter.

Some brands such as 3m 3930 diamond grade can only be cut with a pro series cutter using special blades and well over 400 grams of force.

The primary rationale for blades of different angles is cutting depth.